Foam glass is a thermal insulation material which is mainly used in the building industry. it is produced by the swelling of a mixture between powdered glass and an expanding agent at high temperature. Depending on how the manufacturing process is controlled, various types of foam glass are created.

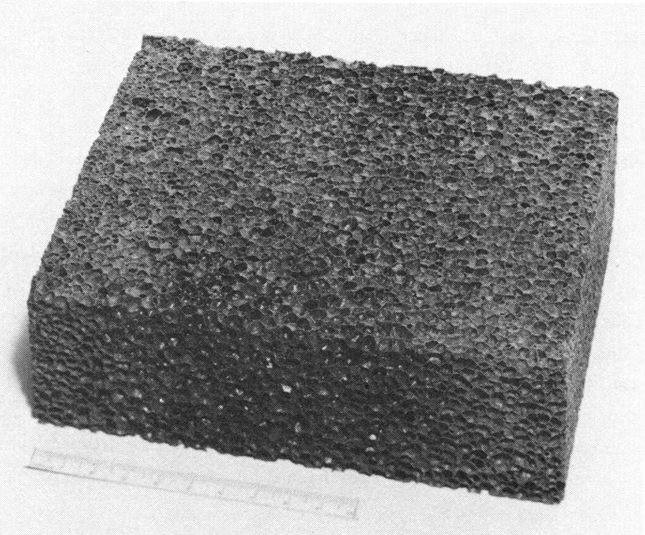

Today, foam glass is manufactured industrially in various countries in tunnel furnaces. These foam glasses are differentiated in terms of chemical compositions and grain distributions of the starting glass powder, in the type and quantity of the expanding agents, and in the time progression of the temperatures (profile) in the foaming- and cooling ranges. Globally used expanding agents include anthracite, high-quality coke and mixtures of anthracite and lime or lime and marble. Foam glass can be defined as a solidified glass mass, which is evenly permeated by a large number of gas cells. Pumice can be viewed as a naturally-occurring counterpart. Fig. No. 1 shows a photograph of one of the large-celled foam glass samples expanded at ETH.

Fig. Nr.1 Large-celled foam glass sample

Even though foam glass has been known about since 19321) no publications regarding systematic investigations of its internal structure and mechanical properties are available. For this reason, this paper attempts to close this gap.

The objective of this work can be described as follows:

- 1)Models are to be found, to allow predictions to be made regarding the fracture mechanics behaviour of “foam glass” in terms of classic structural mechanics.

- 2)The static behaviours predicted using the models above are to be checked with the aid of tests!

- 3)Finding optimum foam glass microstructures which could be possible from a technical process perspective.